COFFEE DRYING AND STORAGE

Presented by the Kona Coffee Farmers Association, September 29th, 2007

Discussion Leader: Kenneth Sheppard, in association with Bob Nelson & Chuck Moss

Disclaimer: This is the text of an “in-house” workshop. There may be errors and omissions. KCFA accepts no responsibility for these, and welcomes comments and corrections or other useful data.

According to Richard Dinker, the State Agricultural Inspector, the biggest assignable cause of green been defects is poor drying practices. Fortunately we can do something about it if we understand something of the principles involved. Our ultimate goal, as in all things Kona Coffee, is to achieve the highest possible quality to serve our customers and maintain our market recognition.

PART I – THE THEORY COFFEE DRYING

OVERVIEW

To be able to develop an efficient coffee drying system it is important to have some understanding of the theory how coffee dries, and, as we are in Kona we are talking of parchment coffee resulting from wet processed coffee. Out of the fermentation tank and after rinsing the bean moisture content of 52% that has to be reduced to 11 to 12% in a uniform steady controlled way without re-wetting. 100 lbs of wet beans contains roughly 5 gallons of water to be evaporated – quite a task.

Intuitively we know that we need a dry atmosphere to remove moisture from coffee beans, but we also have observed in practice that it is not as simple as that. Sometimes our intuition is wrong and leads us in the wrong direction as we try to improve our drying methods and coffee quality.

- THE POWER OF VAPOR PRESSURE

There is a lot of folklore about the drying process some of it right and some of it wrong; we probably all have our own mental image of what happens during the drying process. The actual physics and thermodynamics can get quite complex and many hundreds of books have been written on the subject but for our purposes we need to only come to grips with a few basic principles. Armed with this knowledge we can design and develop better drying systems both solar, mechanical and possibly chemical.

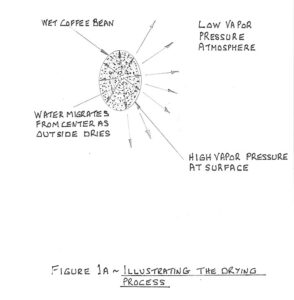

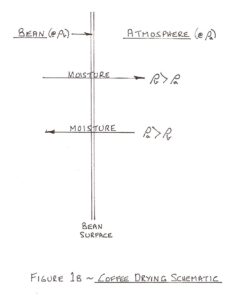

It is not necessary to go into the deep science here. Suffice it to say after we wade through the theory we find that the actual physical driving force behind moisture removal (or increase) is the difference in water vapor pressure between that of the bean surface and the surrounding atmosphere. This is comparable to our climate where air flows from areas of high pressure to areas of low pressure and can be visualized in the same way.

Ref: Sivetz says:

“At the beginning of the drying operation, the coffee (bean) vapor pressure is high and remains constant as long as the surface is moist. After a time, the moisture at or near the surface is exhausted, and more moisture must migrate from the interior of the bean to the surface. This is the so-called falling rate phase of drying. As time goes on, the water begins to be held more and more firmly by chemical forces, such as the bonds of water hydration and of water that is part of the structure of the chemical constituents of the coffee solids. The drying process gradually becomes slower and the surface vapor pressure continually diminishes as time goes on… within moderate limits, drying rate depends much more on the relative humidity of the air than on the dry bulb temperature.”

The upshot is, as beans get drier they become more difficult to dry and are prone to re-wetting.

- SO WHAT IS THIS VAPOR PRESSURE PROPERTY THAT DRIVES THE PROCESS?

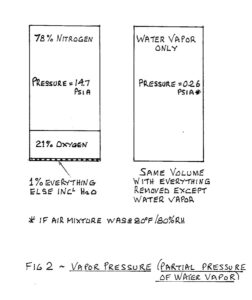

The atmosphere is made up of a mixture of gases, mostly nitrogen 78% and oxygen 21%, the remaining 1% contains all the other trace gases (CO2, argon, neon, krypton etc.) including water vapor. The absolute air pressure of this mixture is 14.7 pounds per square inch (psi) at standard conditions of sea level and 68°F. This is the total force of the atmosphere stacked up from sea level on up on one square inch

If we take a container of this air and a magic pump that could suck out everything except water vapor the pressure would be only 0.26 psi. This is the vapor pressure (or partial pressure) that water vapor contributes. Simply put all the partial pressures of all the constituent gases add up to the total pressure of the mixture.

This is the Gibbs-Dalton Law: P = rnitrogen + roxygen + rwater vapor + rother gases

It is very important to have some understanding of this because we need to manipulate vapor pressure to our advantage to efficiently dry coffee. Vapor pressure and relative humidity are intertwined and both are affected by temperature (which is very useful, up to a point).

r=r100% x Relative Humidity

- HOW DO WE MANIPULATE VAPOR PRESSURE?

There are two basic ways, a) change the temperature by heating the air and b) remove some of the water from the atmosphere by condensing it out in a dehumidifier or by using a chemical desiccant.

- a) Changing the temperature

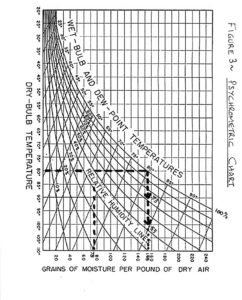

Even slightly warming moist air has a remarkable effect on relative humidity and hence on vapor pressure. There are many thermodynamic formulae we could play with but fortunately Mr. Carrier of air conditioning fame did it all for us in 1911 and reduced it all to the graphical form of the psychrometric chart.

Although it looks complex, a psychrometric chart is just a graph of the physical properties of moist air at constant pressure, consequently there are different charts for different altitudes (something to take into account).

Don’t be too alarmed it looks worse than it is and we are only need to look at a very small portion of it for our purposes.

Some of the lines of interest are:

- a) Dry bulb temperature, this is what your regular thermometer reads

- b) Wet bulb temperature, this what the thermometer would read with a wet sock over it on a windy day. It is also called the dew point the temperature at which the air can no longer hold moisture and some has to go in the form of condensation. This effect is used in the Sling Psychrometer to determine relative humidity.

- c) Relative humidity lines

- d) And for fun the amount of water in air in grains per pound of dry air (7000 grains/lb)

Let’s work an example together. Let’s take a look at what happens when we heat air from say 80°F that is fully wet at 100% humidity or thereabouts, a condition we may find in Kona after a rain.

Starting at the bottom of the chart, follow the 80 degree dry bulb line up until you hit the wet bulb or saturation or 100% humidity line. Now when we heat the air to 90°F it still contains the same amount of moisture so we follow the line to the right at constant grains/lb until we hit the 90°F line.

What do we find?

The intersection lies between the curved 70% and 80% relative humidity lines, at about 73%. So for just 10°F we have dropped the humidity by 27%.

What if we heat it to 100°F?

We get almost 50% relative humidity. 100°F on a well-designed deck is easily reached as many of you coffee rakers know. Mechanical dryers can reach even higher temperatures but there are limits before bean temperature creates adverse effects.

Let’s take a look at the drying potential of air using the chart. Drying potential is simply how much moisture could the air remove before it reaches saturation and can no longer hold any more (dew point or 100% relative humidity).

Following the 80°F dry bulb line vertically until it crosses relative humidity lines we get at 100% relative humidity that it contains approximately 158 grains of moisture/lb of dry air and at 50% relative humidity it contains approximately 78 grains/lb of dry air. So 80°F air at 50% relative humidity has a drying potential of 158-78=80 grains of moisture.

Sivetz: Air at 70°F/85% relative humidity has a 14 grain drying potential, the same air heated to 158°F results in 7% relative humidity with a drying potential of 142 grains.

- b) Removing water

Another way to reduce the vapor pressure of the air is to physically remove some of the water. This may be done with an electro-mechanical dehumidifier or by chemical means such as silica gel.

The cost of energy in Hawaii means that these dryers must be closed loop sealed systems to save energy, there are several working examples that have been developed here and they hold some promise for the future.

I believe there is also some scope to explore the chemical systems further especially for partially sun dried coffee but I do not have any data as yet (anyone with data please let me know). There is at least one of these systems in Kona.

- WHAT HAVE WE LEARNED FROM 1, 2, & 3 ABOVE?

GENERAL PRINCIPLES OF AIR DRYING

Being old in the tooth I remember helping my mother with the clothes washing, no washing machine and no dryer. The washing was hung out to dry on a line and it was quickly understood even at a young age what was going to be a good drying day. The same principles apply to coffee:

- a dry day (low humidity/vapor pressure)

- wind (air circulation/ventilation)

- sun (heat)

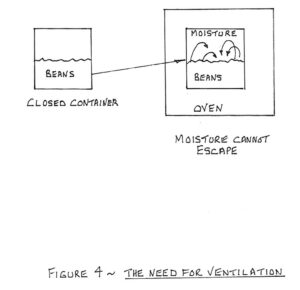

We need exactly the same requirements for our drying systems. The lowest humidity in the air to start with, more heat to lower humidity further, and air circulation to carry the moisture away. The latter is often neglected and some decks have been built with closed sides and doors in belief that heating the beans alone will dry them.

Think about this jar of beans with the lid on. If I put it in an oven for some time and weigh it will still weigh the same as there is no way for the moisture to be removed. Sure, moisture is released into the jar atmosphere but is then reabsorbed when it cools. If I do the same with the lid off the moisture can be carried away with spectacularly different results.

Often times I see decks built across the mauka/makai breeze direction. It is much better to align the deck mauka/makai so that the natural breeze can carry off the moisture from the high humidity layer that collects immediately above the beans.

On the other hand, too much breeze with fan assist may prevent the air from heating up effectively – a balance is required.

PART II – PUTTING THE THEORY INTO PRACTICE

- MECHANICAL DRYERS

Looking at mechanical drying helps understand and reinforce sun drying principles. To a large degree a sun deck is the same as a mechanical dryer; it has a heat source (the sun), it has air circulation (wind) and mechanical agitation (the manual rake).

As a simple example, look at a fruit and vegetable dryer, it has a heater to gently warm the air and a fan to circulate it.

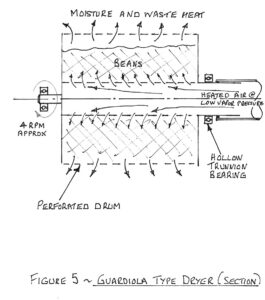

Here is a worked example of a Guardiola dryer to show how much energy it takes to dry coffee from wet:

| Guardiola standard

Load (a lot!) |

Beans loaded in fully wet | Interpolated for a

typical Kona load (smaller) |

| 9150 lb (250 bags cherry) | Wet Beans in @ 52% moisture | 2500 lb (25 bags cherry) |

| 5035 lb | Dry parchment out @ 12.18% | 503 lb |

| 4115 lb (494 gallons) | Water evaporated | 413 lb (50 gallons) |

| 4542,000 | BTU’s required to evaporate moisture | 454,200 |

| 9520,000 | BTU’s applied from fuel oil | 952,000 |

| 47.7% | Efficiency of fuel use | 47.7% |

| 68 gallons | Fuel oil used | 6.8 gallons |

| 3 cents per lb | Cost of fuel oil per lb of parchment | 3 cents per lb |

| Cost of fuel oil (US average) | $15.09 | |

| Cost of propane (US average) | $18.49 | |

| Cost of kerosene (US average) | $18.54 | |

| Cost of electricity

(Hawaii cost at 43.64 cents/kWh)

|

$208.90

(Yes! 41.5¢ per lb of parchment…) |

Note the huge amount of water that has to be evaporated by the sun or fuel.

Now all this assumes drying from wet but what if we mechanical dry from say 20% – this changes to the following:

| Beans loaded in after partial sun-dry | |

| Wet Beans in @ 20% moisture | 553 lb (from 25 bags cherry) |

| Dry parchment out @ 12.18% | 504 lb |

| Water evaporated | 49 lb (5.8 gallons) |

| BTU’s required to evaporate moisture | 53,888 |

| BTU’s applied from fuel oil | 112,949 |

| Efficiency of fuel use | 47.7% |

| Cost of fuel oil per lb of parchment | 0.36 ¢ per lb |

| Cost of fuel oil (US average) | $1.81 |

| Cost of propane (US average) | $2.31 (0.45 ¢ per lb) |

| Cost of kerosene (US average) | $2.20 (0.44¢ per lb) |

| Cost of electricity

(Hawaii cost at 43.64 cents/kWh)

|

$14.44 (2.86¢ per lb) |

- SAFE WORKING TEMPERATURES FOR COFFEE.

There is variation on the recommended safe inlet temperatures (air coming into the dryer) for mechanical dryers.

References on Inlet Temperatures

Gtz-ppp project 2002: Ideal inlet temperature is 113 to153°F/45 to 67°C

CTHAR: 150 °F/66°C max. Start at 95°F/35°C then raise to 140°F/60°C

CTAHR: Inlet temperature 135°F/57°C to 140°F/60°C for rotary dryers, ideally 130°F/54°C

Lauren Gautz three layer dryer tests: 122°F/50C, 126°F/52°C, 129°F/54C in the three layers.

Sivetz: From 52% wet, 180°F/82°C for a few hours, 167°F/75°C for 6-12 hours then 150°F/65°C down to 12% moisture. In certain circumstances temps up to 194°F/90C has been used for a short time but you really need to monitor the process closely, this is profile drying.

However there IS general agreement of the safe temperature of the beans themselves. This also applies to sun drying.

BEAN TEMPERATURE, ABSOLUTELY CRITICAL!

The above heating inlet temperatures are more about managing the drying process for speed and economics. However, of critical importance is bean temperature; again according to Sivetz the following bean temperatures can be tolerated:

104°F/40°C…….a day or two

122°F/50°C…….a few hours

140°F/60°C……for less than an hour

So to a large extent it does not matter so much what the inlet temperature is, within reason, if the bean temperature is not allowed to exceed the above guidelines. This applies to sun drying too and I suspect (without data) that the 104°F/40°C limit is reached quite often especially when the beans are getting dry and are not cooled by evaporation.

As most of this work was done in Latin America, the Celsius temperature scale is used. Often seen are set point numbers of 40, 45, 50 and 60°C. These are nice round numbers to work with and remember, and you will see this if poke around dryers in Kona. Be nosey and ask what temperatures they use and why.

CASE HARDENING

Drying too fast can “case harden” the beans. This is when it forms a hard shell that makes it difficult for the remaining water to migrate from the inside.

3. THE KONA CHEAT

If the dryer inlet temperature does not exceed 104°F/40°C then the beans cannot get any hotter than this. This is what a lot of people in Kona with old Hilo Ironworks drum dryers do; after doing sun drying to get the moisture down reasonably low they run the dryers at the above FIXED temperature until dry, this requires no process controllers or close monitoring of the process as long as the thermostat does no go berserk on you. A few edge up to 113F/45C especially in the early stages if the beans are wettish, the latent heat of evaporation has a cooling effect so the beans will not get too hot, but wise to turn down to 104°F/40°C as the beans dry.

Crude but effective and inherently more safe.

- THE CASE FOR FINISH DRYERS.

As can be seen from the above, to dry beans from wet is very wasteful of energy, but a drying deck that can be kept with a thin bean layer is expensive too. So at some point, as the big processors found out, some mechanical drying is required or they would have to have acres of drying area.

But now, especially at high elevation, where drying was not historically carried out, sun drying has limitations on what can be achieved with limited deck space. Over the years in Kona, farmers have experimented with various small dryers and many are now at the stage of development where they can be of use to more people e.g. Bob Nelson’s dehumidifier dryer and others. If most of the moisture is relatively easily removed by sun drying then it becomes feasible to even use electric power to dry coffee the remaining few percent.

Also I believe most of the drying defects occur on sun decks at the last part of drying where beans may get re-wetted many times as the night humidity increases.

A quick look at the Guardiola study above shows that even with electric heating and no further efficiency improvements it maybe costs $14 to dry from 20% to 12.18% for 500 lb of finished parchment; not too shabby all things considered and may be financially better to get a small 500 lb capacity dryer than build a bigger deck. More efficient designs and propane-fired units would be even cheaper to run.

- SUN DRYING VS MECHANICAL DRYING.

From the above we have seen that functionally there is little difference. Is there any difference in resultant coffee quality and cost effectiveness?

| Sun Drying: | Mechanical Drying: |

| • Traditional, feels good, should be pursued for that reason alone.

• Adds mystique for the coffee consumer and marketing efforts. Gently sun dried on the slopes of Mauna Loa sounds better than bunged in a propane heated drum until done. • Ecologically sound except for the deforestation required to build it; sun heat is free and with Global Warming getting better all the time. • More difficult to really mess up but can be done if we don’t pay attention – don’t go to Costco on a really sunny day if you are near the end of the run! Been there done that. • Needs a lot of attention and labor to rake, especially if done as it should be. • Bean depth limited to 2 to 4 inches (Sivetz figure – too aggressive for Kona, see Section 8.) • Doesn’t work too well at night although some drying may occur when the beans are really wet and air conditions are favorable • First cost can be relatively cheap if one builds it oneself but a 500 sq ft deck will cost $5000? plus for materials depending on style/terrain. $2000 for concrete pouring alone plus 6-7 yards of concrete at $?/yard • Needs a good drying site away from shade and pointing Mauka-Makai, low elevations better. • Drying takes 7 days or more, and even more at higher elevations. • Coffee also re-moisturizes under adverse changes in vapor pressure due to rain and/or the natural increase in humidity when the temperature drops at night (hence the put the coffee to bed method below). • Deck materials have different performance e.g. wood vs concrete vs wire mesh etc.

|

• Has an industrial feel to it that some people are not comfortable with.

• Many are convinced it does not dry as well as a sun deck, “coffee tastes better with sun drying” • Expensive to buy and run if drying from wet. • Not ecologically sound. • Can easily mess up a big load of coffee especially if relying on process controllers or operators who do not pay attention. • Twice as fast as a sun deck because it can run 24 hours per day vs 12 for sun drying. • Well set up and run it can dry coffee very well. • If used as a finish dryer it can clear the decks for the next round or other peoples coffee and save building a bigger deck.

Note: Big processors tend to put the coffee on the deck for a day or two then into the dryer. This saves both deck space and the need to have large or many dryers as well as the economies of fuel use. Also beans need to be at least surface dry before going into a dryer as wet beans tend to clog up the works. |

So back to the big question which is best? Logically, objectively and without bias the best system is mechanical drying with or without a sun pre-dry because the process can be controlled to a finite degree.

However the traditional sun drying system with the improvements and methods recommended later certainly produces high quality coffee. As in most things it depends on the care and dedication of the farmer, both systems can ruin otherwise good coffee. I prefer sun drying from the traditional and ecological point of view, but I am not against mechanical drying.

Remember Rule One: After you pick coffee from the tree only bad things can happen, unless we limit the damage by following good practices.

- SUN DECKS

Sivetz says that sun drying decks only have a 7 to 13% efficiency for the energy falling on the coffee, but do we care? No and yes. No because the energy is free but yes because we also want to dry in a reasonable time and in such a way as to maximize quality. Deck design is crucial in getting as much drying time into the day as possible and limiting the amount of rewetting.

Deck Materials:

Both wood, concrete, wire mesh and even tarps are regularly used, all work reasonably well. Covers can be none, traditional hoshidana tin, poly sheeting (greenhouse UV resistant grade) or Lexan (polycarbonate).

Wood: Plywood is a reasonably economic solution but it does wear out. It should be untreated but with exterior glue. Annual treatment with a wood preservative may be useful but do not do it just before the coffee season as flavor taints may show up. After the last drying is a good time.

Solid T and G planks last a bit longer but the huge amounts of joints makes it hard on the coffee raker, joints and nails invariably lift, rakers soon learn not to point their rake at their throat! It is very expensive too.

Concrete: For those with a level area this may be a good option and is relatively inexpensive if you do your own site prep. It absorbs and releases moisture but after a time it is somewhat stable. A vapor barrier material would be a good idea between the concrete and the fill. Concrete is slow to heat up but residual heat built up during the day probably compensates by extending the drying time as evening approaches.

Tarps: A reasonable low cost start up approach if you are prepared to deal with the difficulty of raking. It has the added benefit that when drying has halted, the parchment can be bundled up in the tarp to prevent re-wetting and allow the bean moisture to equalize.

Wire mesh: I am ambivalent about wire mesh decks but some swear by them. Certainly when the beans are wet they will dry really well on mesh, but as time goes on they lose efficiency because the bean mass does not heat up as well without a heat sink surface to help build up and hold the heat. Also they are very prone for re-wetting the parchment as the thru flow and increase in beans exposed to night-time high humidity air is significantly increased.

It is difficult to get at the beans to rake them unless area reducing walkways are built in.

A good compromise might be a part mesh/part wood deck. When the beans have been partially dried on the mesh they can be moved over to the wood part to finish.

Cover Materials:

Andy Roy of Bayview Farms relates that his uncovered drying decks dry in one day less than identical covered ones. This may lend more explanation to the requirement for ventilation. He is also at 500 feet which helps. So the pioneer Japanese farmers were pretty smart with their roll-away tin roofs and I wouldn’t mind betting that they even dried to some degree when rolled back over as the tin will heat up even with some cloud cover.

If you are not going to be around all the time to roll over a cover then you need some kind of transparent roof that will pass sunlight.

Greenhouse poly works well, is cheap but last only 5 years, but it is still cheap to replace it.

Lexan lasts longer but is very expensive and there is some question of light transmissibility as it ages – some older roofs are positively opaque.

Depending on your purse I tend to favor the greenhouse poly approach.

- THE VICIOUS CIRCLE

Even at low elevations there will come a time when you will not be able to get the coffee dry. You find that the coffee is wetter in the morning than it was the day before and this will carry on for many days. It is because the night-time humidity rises and the dry coffee has a lower vapor pressure (see psychrometric chart) than the humid air, so it reabsorbs moisture. The solution is to ‘put the coffee to bed’ at night. First of all I would recommend that you keep a simple chart of moisture levels in the afternoon and morning, it will then be obvious when you are entering the vicious circle.

Here’s the trick: When you have judged that the coffee is as dry as it is going to get that day (about day 5 or 6 say) scoop up the coffee and place it in a sealed container, say a plastic bin or garbage can with tight fitting lid or even wrapped in a tarp bundle. If nothing else, heap the beans into a pile, cover with a tarp and dry burlap bags and weigh down the edges.

This will do two things: a) the bean moisture content will tend to equalize and be more uniform and b) the moisture content is held close to the last reading you made as more moisture is prevented from entering the beans at night.

On the following morning put the beans back out on the deck when it has warmed up and/or if you have a humidity gage when the humidity looks to be in a good drying frame of mind.

Repeat the following days until done.

- MECHANICAL DRYERS FOR THE SMALL FARMER

There are not many small dryers available but that is changing. The old Hilo Ironworks dryers are no longer made but they are quite good if you can find one. There are one or two propane fired tray dryers from South America around but they seem a bit difficult to use.

Many in Kona have been developing systems which use a dehumidifier rather than heated air. Bob Nelson has developed this system quite extensively and I will let Bob explain the system and the economics.

Over time I think mechanical drying is the direction we will go in Kona, with the new generation of coffee farmers with more resources available (at least when they first start!) Processing is now being done at higher elevations than may be prudent, which will require a more technical solution.

PART III COFFEE STORAGE

OVERVIEW

To a large extent the issue of coffee storage is the reverse of coffee drying and the same theory of moisture migration applies i.e. moisture will always move from the highest to the lowest vapor pressure. The ideal storage conditions are somewhat elusive but we attempt here to make recommendations at least for a start point

But first we must understand EMC; if you come to understand this alone then your day will not have been wasted.

- EQUILIBRIUM MOISTURE CONTENT OR “EMC”

Equilibrium means “in balance” in this case the balance is between the moisture content of the bean and the surrounding storage air. Simply put if we had an atmosphere that was constant at say 65% Relative Humidity the coffee beans moisture would stabilize at 12% forever; for each relative humidity there is a stable moisture content and not just for us but for any dry commodity.

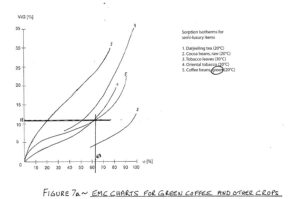

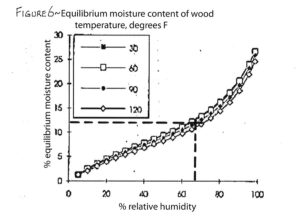

Wood EMC chart.

I found this chart for wood that highlights that we are not alone and found it uncanny in that it matches pretty close the situation with coffee

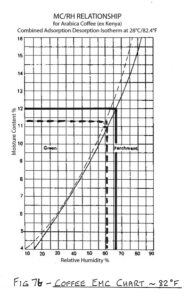

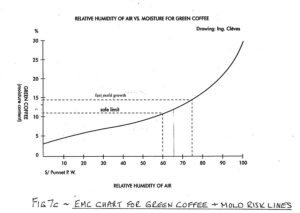

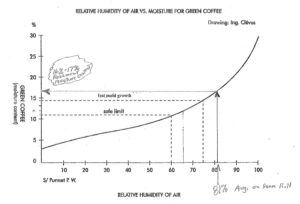

Coffee EMC Chart.

Here is a generic chart for coffee. If you look at each humidity line you will see a corresponding moisture content. If the atmosphere changes wetter (or drier) the moisture content of the bean will migrate in that direction or if up and down then the bean will dry-reabsorb-dry…. not good.

So it all very simple, yes it is but not quite……

There is quiet a bit of variability of data between Researchers, Parchment and Green and storage temperature.

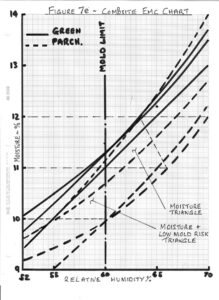

The Coffee EMC Chart ~82F

EMC Chart for Green Coffee + Mold Risk Lines

The following chart is an overlay from various sources: Sivetz, Punnet,Henderson, Kulaba, Stirling, Container Handbook. Oddly we do not have one from a study done in Kona at our elevation, perhaps we should rectify that.

As can be seen, there is a general but not a precise agreement. A lot of the variation comes from the fact that the EMC charts vary with temperature and probably elevation, I have not been able to find a complete set of “isotherm” data for coffee so we have data here from 20 to 28°C/68 to 82°F. However I think this shows us the sweet spot within which we should be working.

Another wrinkle which complicates matters a bit is the need, ideally, to keep moisture below 60% RH to avoid mold growth. This drives us into an area where some may say the coffee may be too dry, especially parchment, because the resultant green may be 1% less after milling.

So there you have it, this is the area you should be aiming for ideally and if you are outside these conditions it can result in deleterious results. Parchment above 13% is almost impossible to mill and some mills will not accept anything above 12%, Some beans may get squished flat being too soft. Over-dried coffee lower than 9% also leads to some flavor and milling issues such as cracked beans.

70% RH has often been quoted but I believe we need to be a bit lower than this to meet a good long term bean dryness and obviate possible mold issues so the 50 to 65% is not a bad ball park to play in.

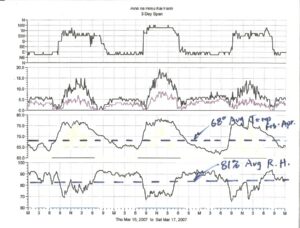

As always do not trust one Hygrometer or expect it to always be accurate. The best policy is to maintain a chart of RH and actual bean dryness, this takes care of varying RH conditions, temperature and elevation and also shows if you are inexplicably trending in the wrong direction. It doesn’t have to be fancy, just a sheet of squared paper will do.

- TEMPERATURE.

Temperature, in my opinion, is a far lesser issue than humidity although ideally, as recommended in the Shipping Container handbook it should be 5 to 25°F/41 to 77°F (mean 15C/59°F), so you can see that we in Kona can probably keep below the maximum (but beware heat from DH units!).

Sivetz says that flavor loss is perceptible after a week at 90°F/32°C but generally we don’t operate there or do we??

Interestingly they also quote Moisture content as 10%(critical 12%, this is for green coffee) and EMC of 50-65 % RH.

- STORAGE WITHOUT AIR CONDITIONING.

Basically coffee should never be stored unprotected in the country it is grown in i.e. the tropics. In Brazil it is on a boat as soon as possible to drier climes. Until recently this was the situation in Kona with the larger mills moving coffee as soon as possible, but now there are air-conditioned warehouses / containers.

The small farm scene has also changed with the many and growing number of small estates that require coffee to be stored from one season to the next.

Also it seems well proven that new harvest coffee requires a maturation period of two to three months before roasting or the coffee may taste “grassy”.

So what to do?

- If you are in a high humidity area your coffee will get progressively wetter faster. If you still decide to go ahead it may be better to get your parchment milled before it reaches 13% and store as green. It cannot be sold as Kona above 12.2% green but it will roast without serious issues. This option is probably better overall than re-drying parchment coffee to get it milled.

- Make friends with someone lower down in a drier area, someone you can trust J

- Many mini-storage units are in low humidity areas which is an option but check on their temperature extremes, security and insurance.

And now for an exciting new development that hopefully will be the answer to a maiden’s prayer. I have been following the development of hermetic storage methods for over ten years and there may now be a practical solution on the market. Chuck Moss will describe the use and benefits of the “SuperGrainbag” from Grainpro. We are looking for farmers to join in this experimental program to collect data in the Kona situation.

A Low Cost Option for Parchment Storage

On farm storage of parchment involves a situation in which the natural environment isn’t good for storing parchment. An artificial environment for parchment storage costs money to build initially, and involves a continuous expenditure of energy to maintain. A low cost alternative is available, which may be suitable for storage on many small Kona farms.

A typical small farm is at 1,500 foot elevation, and uses sun drying to bring the parchment to a moisture content of 11% to 12%. The parchment is stored until needed over the remainder of the year until next years crop comes in.

While the picking season goes on the parchment can be left on the drying deck in burlap bags and will stay in that “sweet spot” of moisture content. But, once the season is over the environment averages 68 deg F, 85% humidity, and the moisture starts migrating back into the parchment. The parchment eventually reaches equilibrium at somewhere around 17%.

A low cost alternative to using an active, artificial environment is to put the parchment in an airtight bag when it is in the 11%-12% moisture content range. The bag acts as a barrier and keeps new moisture from migrating into the parchment. The coffee, water and air inside the bag maintain equilibrium in the “sweet spot” of moisture content. The bags are small enough that parchment can be withdrawn periodically from one bag at a time without letting moisture into the rest of the bags.

The bags that are available are sold under the name of “Grainpro” and are part of a system of hermetically sealed grain storage products, ranging in size from hundreds of tons in cocoons, down to 50 lbs in a single bag. The system has been tested on coffee, including cupping for taste, and found to be far superior to storage in burlap bags alone. The three layer plastic bag fits inside a normal burlap bag for physical support, seal easily and can be reused. In small quantities, the bags sell for $2.50 per bag.

A data sheet and the instructions explain the system and how it is used along with providing the phone number and website link for more information. www.grainpro.com. An article in the Tea and Coffee Trade Journal (www.teaandcoffee.net/1105/special.htm ) describes a test on the system.

In summary, storage options for parchment include storing the coffee in a dry natural environment (not commonly found on tropical coffee farms), in a relatively dry (approx 60% relative humidity) environment, or in a hermetically sealed bag, which if used five times to store 50 lbs, costs about 1 cent per pound per year of storage.

- STORAGE WITH AIR CONDITIONING.

This method is now being practiced extensively with mixed results.

A few guidelines:

- The container may be a box or a room, the smaller the volume the less air has to be conditioned.

- The room needs to be insulated to prevent temperature extremes, even out the day and night temperatures and limit heat losses if AC is used.

- Unless you want to dehumidify the whole of Kona the walls (and door) must be impervious to the transmission of water, sheet rock won’t do it. Use vapor barrier material such as heavy gage poly sheeting, two layers if you like. Tyvek may work but I am not sure of its vapor transmission rates as it is designed to “breath” but maybe OK certainly better than nothing. The material can be fitted either side of stud wall, probably better on the inside so that the insulation does not act as a moisture reservoir.

- A metal container may be good but watch for condensation conditions and keep coffee away from direct contact with the wall. Needs insulation/AC.

- Install a moisture gage that can be read from outside the room, there are even wireless ones available now. This saves opening the door although pickup is not that great in a short time but the DH unit has to recover by running.

THEORETICALLY: If your room has perfect moisture barriers and sealed doors, once the room has reached equilibrium the DH unit should not need to run…… food for thought.

- AIR CONDITIONERS vs DEHUMIDIFIERS

There are AC units, DH units and combined AC/DH units.

If you are at high elevation then a DH unit may be all you need as the average ambient temperature is below our guideline value. I recommend the “in-room” kind because the exhaust vent (and heat) is a simple 5 inch duct connection. Make sure you get one (not all do) with the drain pipe option and not a tray to be emptied.

Some DH units put out a bit of heat but with a well sealed room they should not be running very much, get the smallest one practical.

At lower elevations heat may be a problem and AC may be required. Many fit a DH unit and an AC unit even though an AC unit has some DH function. Now there are some in-room AC/DH units available but take a look at the specs on how they work together, many are either on AC or DH but not at the same time. You need one that can be programmed for what you need.

Once you get into AC/DH we are talking electric energy from HECO at now 43¢ per kW hr. If you don’t want a huge energy bill make your space airtight, water tight and insulated.

Insulations: the usual pink stuff, Styrofoam, or aluminized bubble sheet which also acts as a vapor barrier.

- HOW LONG WILL COFFEE STORE?

In parchment form I would say one year no problem, in ideal conditions maybe two. For green, maybe one year is the limit even in ideal conditions because the outer layer is exposed to the atmosphere and loses its luster. It may be cosmetic but will affect price.

REQUEST FOR RESEARCH ASSISTANTS.

We are looking for farmer volunteers to take part in some of the efforts described above.

Especially:

- Variation of RH/Temp in a closed container.

- Monitoring of coffee in SuperGrainbags, followed by cupping with standard storage as control

- Maintenance of long term records of humidity and bean moisture in storage rooms to be presented next year to fine tune the recommended ideal storage conditions.

- Measure air temperature and bean temperature on sun decks